Superior Casting

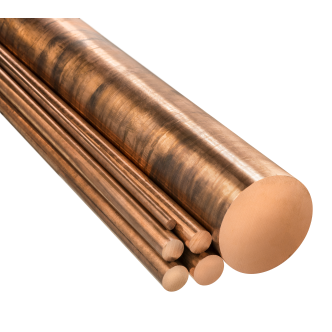

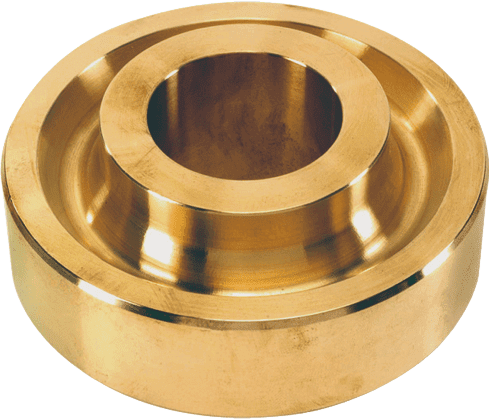

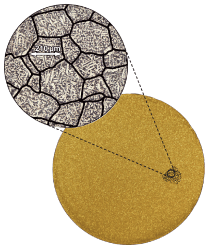

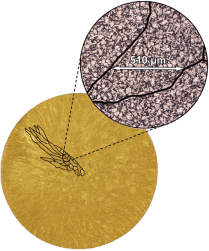

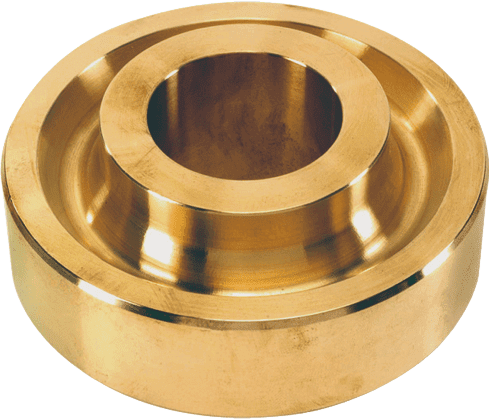

Introducing MICROCAST®, our patented high-performance aluminium bronze and speciality copper alloy production technology that delivers the most uniform grain size with the most outstanding wear resistance.

MICROCAST® is based on exclusive magnetic steering (Magneto-Hydro-Dynamic) at the casting furnaces, which produces an extremely fine grain with uniform microstructure that promotes dispersion, creating consistent quality and durability.

A century of engineered excellence

Since 1914, AMPCO METAL has worked with industry partners across the Aerospace, Automotive, Steel & Titanium industries, as well as Marine, Oil, Gas & Chemical, along and a host of others., across a range of applications, including friction & wear, corrosion resistance and heat & electrical conductivity. This unparalleled experience, combined with our technical expertise and engineered alloy excellence mean we’re able to be a global partner in creating metal solutions for our customers.

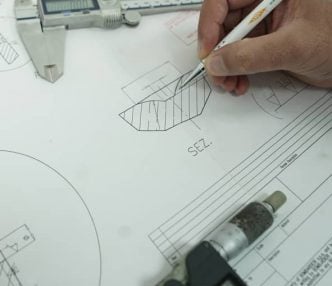

Technical Consulting

- Requirement Gathering

- Material Analysis

- Market Research

- Technical Advice

Application development support

- Existing Applications

- New Applications

- Case studies

- Knowledge Articles

Product Development

- Personalized alloys

- Material development

Production

- Production of alloys from scrap and pure metals in different shapes and sizes through our various casting processes

Warehousing

- Asia

- Americas

- Europe

Cutting Operations

- Band saw

- Plate saw

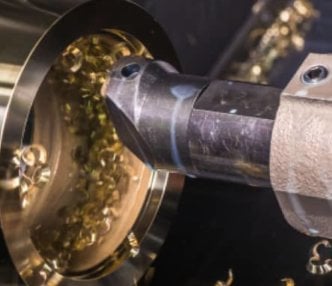

Machine Operations

- CNC turning

- CNC milling

- Turn mill

- Wire EDM-ing

Inspection & QC

- CMM

- Height-gauge

Distribution

- Global Offices

- Ship anywhere

Find the best for you

Browse our world of metal offerings below and find the right metal solution for your requirements. For over a century, we’ve worked closely with customers across the globe to deliver the world’s best metal solutions that suit their requirements.

Materials for Hydrogen Applications

See moreAdvanced Solutions

See moreSteel Industry

See moreCorrosion Resistance

See morePlunger Tips

See moreGravity Die Casting

See moreTube Forming

See moreTube Bending

See moreDeep Drawing

See moreResistance Welding

See moreMetal Forming

See moreDie Casting

See morePlastic processing

See moreWear Resistance

See moreLet us help you find the best.

Contact AMPCO METAL today so we can engineer a solution that works for you.

Contact usLatest from AMPCO

Aufregende Neuigkeiten: AMPCO METAL erwirbt Schmelzmetall-Gruppe

Sehr geehrter Kunde, Wir freuen uns, Ihnen einige aufregende Neuigkeiten mitteilen zu können. AMPCO METAL hat zum 17. Oktober die

Read more

AMPCO METAL Acquires Schmelzmetall Group: Expanding Excellence in Copper Alloy Solutions

Dear Customer, We are thrilled to share some exciting news with you. AMPCO METAL has acquired the Schmelzmetall Group as

Read more

How to significantly reduce weld spatter thanks to AMPCOLOY®

Weld spatter occurs during welding, causing extra costs, equipment damage, and safety risks. AMPCOLOY® is a copper-based alloy with high

Read more