Resistance Welding

Resistance Welding Solutions: Alloys & Precision Machining

AMPCO METAL’s leadership in resistance welding is built on extensive experience and unparalleled expertise in the field. Committed to innovation, our team has a deep understanding of the resistance welding process, allowing us to continually refine and develop cutting-edge solutions.

- Expertise and Innovation: AMPCO METAL is a leader backed by extensive experience and expertise in the field. Committed to continuous innovation, we refine and develop cutting-edge solutions to meet the evolving needs of the industry.

- Comprehensive Product Offerings: We offer a wide range of high copper alloys for various resistance welding applications. Alloys such as AMPCOLOY® 83, AMPCOLOY® 944, and AMPCOLOY® 972 excel in various welding components.

- Performance Excellence: Specific products, such as AMPCOLOY® 972, significantly increase the life of welding plates, exceeding the life of standard plates by more than four times.

- Understanding Industry Challenges: AMPCO METAL understands the unique challenges of resistance welding across various industries.

Our Expertise

Thanks to our extensive experience and expertise, we are a leader in the field. Our team deeply understands resistance welding processes, allowing us to improve and create cutting-edge solutions continuously.

Our alloys exceed the industry’s evolving demands.

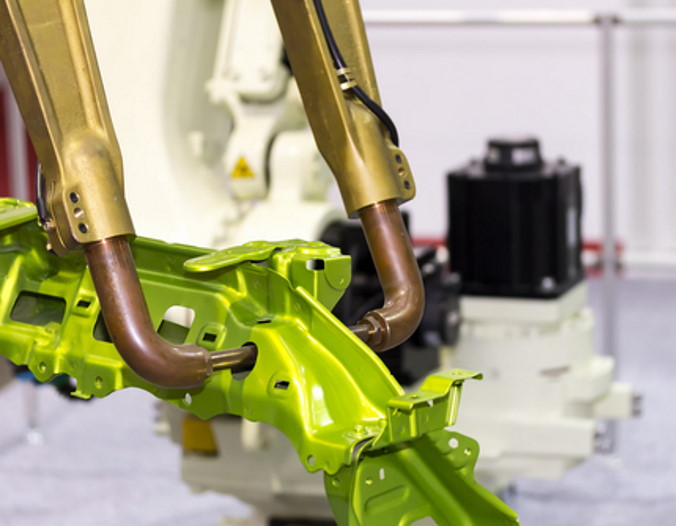

From clamping elements and spot welding plates to robotic MIG/MAG welding nozzles and welding electrodes, AMPCO METAL’s proficiency in resistance welding is evident in every facet of our product offerings.

Our Products

At AMPCO METAL, we offer a wide range of high copper alloys for various resistance welding applications. For clamping elements, AMPCOLOY® 83 and AMPCOLOY® 944 stand out for their exceptional resistance to weld spatter. For spot welding, AMPCOLOY® 972 significantly increases the life of CuCrZr plates, providing more than four times the life of conventional plates.

For robotic MIG/MAG welding nozzles, AMPCOLOY® Nozcap reigns supreme, offering unmatched resistance to weld spatter. For spot and seam welding electrodes, our alloys, including AMPCOLOY® 95, AMPCOLOY® 940, and AMPCOLOY® 972, ensure trouble-free performance even at elevated operating temperatures. These meticulously crafted products embody our commitment to delivering high-performance solutions that improve the efficiency and reliability of resistance welding processes across multiple industries.

Why You Should Choose Us?

We pride ourselves on being more than just a supplier; we are your trusted partner. Contact us today to explore how our cutting-edge alloys and deep industry expertise can benefit your projects. Our dedicated team is ready to collaborate with you, ensuring your applications achieve unparalleled performance and efficiency.