MICROCAST® TECHNOLOGY

AMPCO METAL produces a number of engineered high performance aluminum bronze and specialty copper alloys using a patented technology called MICROCAST®. Based on the exclusive magnetic steering (Magneto-Hydro-Dynamic) at the melting/casting furnace, this manufacturing process produces an extremely fine grain and uniform microstructure, promoting excellent dispersion of the alloy chemical elements for consistency quality and durability.

Benefits of MICROCAST® AMPCO® alloys

AMPCO METAL’s patented MICROCAST® manufacturing process for continuous cast rod, rectangle and tube, affords the following benefits:

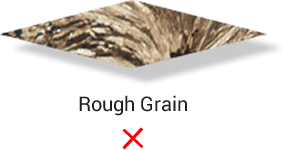

Fine and most uniform grain size available vs. standard products.

Exhibit stable properties over the wide range of working temperatures, similar to their wrought equivalents.

High specific strength, allowing components to be fabricated in smaller dimensions, saving component weight.

High tensile and fatigue strength available in a non-galling bearing and bushing material.

Outstanding wear resistance when properly lubricated.

Commercial Bronze

Standard Cast

AMPCO® Bronze