by Admin | Oct 28, 2024 | AMPCO News

Dear Customer, We are thrilled to share some exciting news with you. AMPCO METAL has acquired the Schmelzmetall Group as per October 17th, a leading Swiss-based producer of copper alloys, including Beryllium-containing alloys and other high copper alloys such as...

by Admin | Apr 3, 2023 | AMPCO Blog, AMPCO News

Weld spatter occurs during welding, causing extra costs, equipment damage, and safety risks. AMPCOLOY® is a copper-based alloy with high resistance to heat and wear that prevents spatter by reducing surface adhesion. Weld spatter is the term used to describe the small...

by Admin | Apr 3, 2023 | AMPCO Blog, AMPCO News

When it comes to resistance welding, choosing the right electrode is crucial for a strong weld. High copper alloys have proven to be a great choice for spot and seam welding due to their electrical and thermal conductivity and wear resistance. Resistance welding is an...

by Admin | Mar 20, 2023 | AMPCO Blog, AMPCO News

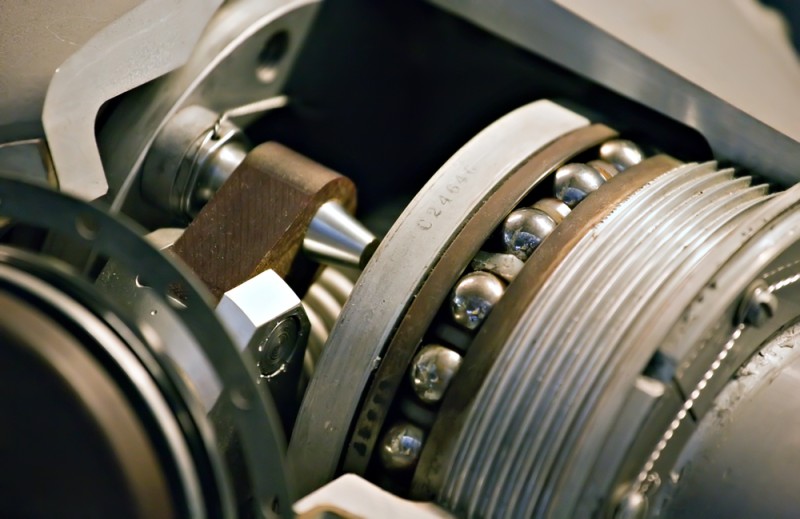

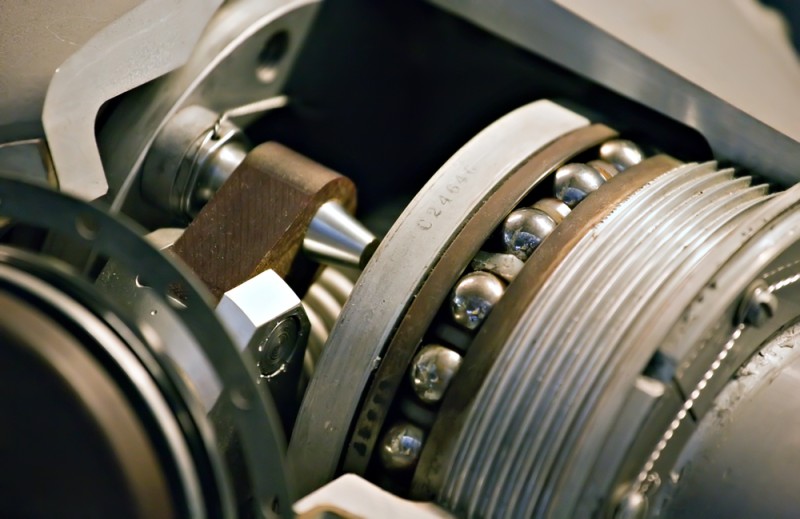

Aluminum bronzes are often used in industries when wear-resistant materials are needed. AMPCO METAL has developed a technology that makes Aluminum Bronze even more wear-resistant to better support companies in wear-intensive applications. Are regular downtimes, and...

by Admin | Mar 20, 2023 | AMPCO Blog, AMPCO News

Various pressure welding processes are used in the welding industry. Resistance spot welding is one of them. This blogpost explains the process of resistance spot welding, its advantages and what must be considered. Resistance spot welding is one of the most...

by Admin | Mar 20, 2023 | AMPCO Blog, AMPCO News

The RWMA classification system is used in resistance welding to select the appropriate filler metal for a specific application. By choosing the appropriate RWMA class, engineers and welders can ensure consistency, quality, efficiency, and cost savings. RWMA classes...