Plastic processing

Plastics processing refers to the manufacture of plastic products. In plastics processing, products are manufactured by processing and producing semi-finished products, molded parts, films, or fibers from plastics. The raw plastic product is usually supplied as granules, powder, sheets, or films.

For processing, the plastic in the form of granules or powder is usually heated and cast, sprayed, calendered, extruded, pressed, blown, or foamed. Accordingly, the primary shaping processes are of particular importance in plastic processing. In addition, if additives are added to plastics to achieve or improve specific properties, this is referred to as compounding.

Different methods of plastic processing

As discussed above, the primary shaping processes are critical in plastic manufacturing. There are quite some methods to be distinguished. Some of the more important ones are listed below:

Extrusion

In extrusion, the plastic is fed via a hopper into a barrel in which a screw runs. This is the extruder. The screw has different sections with different pitches. These are used for melting, homogenizing, degassing, and compressing. Extruders are used in a wide variety of ways. They are used to produce granules, recycle plastic, and manufacture profiles, sheets, textile fibers, and films. In film production, the extruders are equipped with a slot die and/or work with a calender. In the case of multilayer films, several extruders are often required simultaneously to manufacture a film product.

Calendering

Calendering is the process of shaping plastic. It involves a series of hard pressure rollers to finish or smooth a plastic sheet. It is used mainly for producing films, thin sheets, and flooring.

Rotational molding

Rotational molding is a special production process used to manufacture large, hollow, seamless plastic parts. During production, molten plastic granules are deposited on the inner surfaces of the rotating mold as it cools. Due to the nature of the rotating mold, different wall thicknesses can be achieved even within a single mold.

- Foaming

Foaming can be divided into three categories. During the chemical foaming process, the gases that foam the material are released during polymerization. During the physical blowing process, low boiling liquids are added to the reaction mixture, which evaporates during polymerization to foam the typical gas bubbles. Finally, during the mechanical blowing process, a gas is injected into a melt of the plastic while stirring.

- Injection blow molds

In blow molding, a thermoplastic preform is inflated in a mold. The compressed air causes it to adhere to the inside of the mold and hold it in place as it cools. This process is mainly used to manufacture bottles, drums, car tanks, and the like.

What is injection molding?

However, injection molding is the most popular primary shaping process used in plastic processing. It is a great manufacturing process, which is especially well suited for mass production. Any parts produced in large volumes made of glass, rubber, metal, or plastic are typically created through injection molding. The process is straightforward: Molten plastic is injected into a mold, cooled down, and out pops the plastic product. It comprises four stages: clamping, injection, cooling, and ejection.

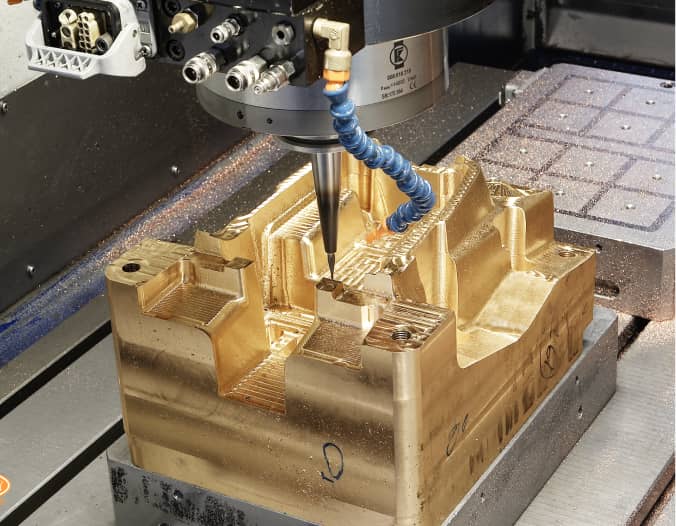

As the cooling phase is the stage that takes up the most time, it is also the lever to increase productivity. This is where the secret weapon of injection molding comes into play: Copper! Thanks to its unique properties, copper-based alloys like aluminum bronze or beryllium bronze can reduce cycle times and increase productivity by up to 80 percent! This allows companies to save 10 – 40 % of their production costs.

Reducing cycle times is hereby just one reason for the saving potential of aluminum bronzes. The other half includes a reduced rejection rate. In addition, warpage can be greatly reduced thanks to the superior thermal conductivity of copper-based alloys. This is due to improved cooling as molds made of aluminum bronze distribute heat more evenly than steel molds.

Why is aluminum bronze is the best alloy for plastic tooling?

Aluminum bronze offers moderate hardness and outstanding conductivity. Thanks to their excellent heat transfer properties, aluminum bronze can drastically speed up the cooling phase, leading to reduced cycle times, increased productivity, and ultimately reduced manufacturing costs.

Even though aluminum bronze is already a good solution, the premium solution for injection molding is beryllium bronze. These alloys combine good strength, wear resistance, high-temperature resistance, and high toughness with excellent conductivity. That is why beryllium bronze is widely used in plastic injection molding, inner mold inserts, cores, die-casting punches, and many more.

AMPCO METAL has developed special high copper alloys called AMPCOLOY®. This polished hard version of copper alloys without coating or lead and clean trace elements are engineered with exceptional conductivity, high strength, and unique wear characteristics, delivering unique benefits.

Overall benefits of AMPCOLOY® and AMPCO® Aluminum bronze

- Improved productivity

- Better product quality

- Longer service life

- Lower machining costs

Furthermore, both AMPCO® 18 and AMPCO®21 are superior metals used for friction applications in molds, which can solve most wear and seizing issues. Our precise, high-conductivity, high-performance AMPCOLOY® alloy range is the ideal supplement to AMPCO® specialty bronzes. These high-conductivity copper alloys are produced with greater care than commercial alloys, with virgin metals and stringent controls to guarantee uniformity and unvarying quality. For these reasons, AMPCOLOY® alloys are extensively used in molds as inserts for the injection, extrusion, and blow molding of plastic parts for various industries – especially the automotive industry, as well as the greater plastics industry.